Call us at 737-260-7939

Your Local Partner for Reliable

Laser Cutting Services

Call us at 760-452-3531

LASER CUTTING & FORMING SERVICES

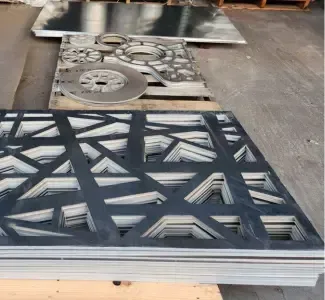

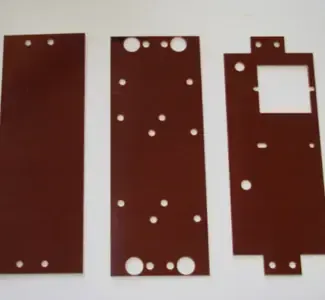

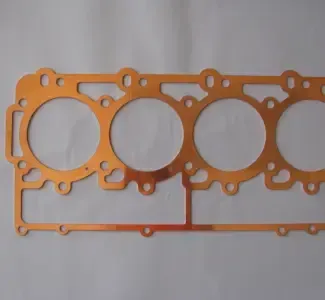

Specializing in laser and waterjet cutting of metal plates, gaskets, panels and custom components, we partner with OEMs, Contractors, and Fabricators to provide high-quality parts with short lead times.

Our state-of-the-art facility in San Marcos, California enables us to efficiently cut and form a broad range of parts at both low and high volumes.

With low setup fees, high production capacity and a fast turnarounds, we make it easy to work with us!

Fill out the form and we'll be in touch in 2 hours or less!

METAL FABRICATION

Elevated Steel is your go-to company for metal fabrication. We are a custom fabricator and designer that offers a comprehensive range of services.

Design assistance

Fabrication (steel, aluminum, stainless, and more)

Welding

Finishing (powder coating, galvanization, wet coating)

Assembly

nstallation anywhere in the U.S.

We use only the best materials available to create strong, long-lasting products and work closely with our clients to provide specialized solutions that meet their demands. Keeping up with the latest technology and best practices are just some of the ways we’re striving to be your resource for all aspects of metal fabrication.

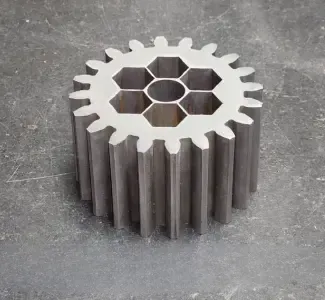

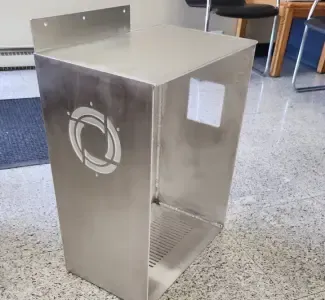

FABRICATION CAPABILITIES

With our fully-equipped 3,000 sq ft fabrication shop in Southern California and a team of highly skilled machinists and welders, there's almost no job that we can't handle. Whether you need a 5 custom panels or 5,000 complex mechanical components, we have the capacity and the expertise to get you a quality product at a competitive price delivered on time.

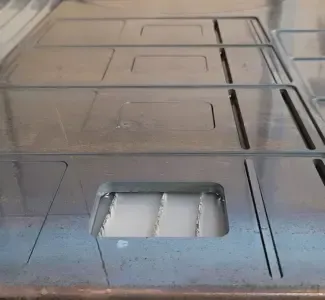

CUTTING & FORMING

5 x 10 Bystronic CNC Laser

Capacity: 72"x144" and 3/8"

5 x 10 Waterjet

Capacity: 60×120″ and 6″ thick, 0.005″ min tolerance

51″x35″ 150W Gantry CO2 Laser

Bystronic 10', 100 Ton CNC Press Brake

Titan 25 Ton, 36" Press Brake

SECONDARY OPERATIONS

Punching: Amada Vipros 255 Turret Punch

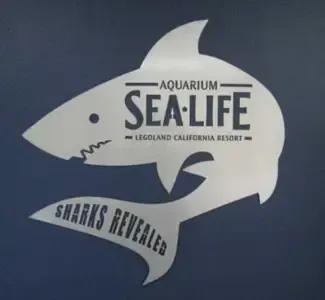

Engraving: 60W Fiber Laser

Flexarm Thread Tapping (up to 1.25″)

Edge Beveling (up to 1″)

Chamfering

Part Deburring

Finishing & Coating

MATERIALS

Our modern, flexible equipment allows us to efficiently process a wide variety of materials. From acrylic and stainless to carbon fiber and exotic alloys, we've got you covered!

METALS

PLASTICS & COMPOSITES

Steel

Stainless Steel

Aluminum

Brass

Tool Steel

Inconel 615 & 718

Brass Alloys

All Other Non-Toxic Metals

Acrylic

Carbon Fiber

HDPE

Plexiglass

Foams

Plywood

G10

UHMW

Nylon

Fabric

& Most Other Materials!

COMMON APPLICATIONS

MECHANICAL PARTS

DECORATIVE PANELS

BOXES & ENCLOSURES

BUSBARS

BASEPLATES & EMBED PLATES

SIGNS

PLASTICS & COMPOSITES

FLANGES & GASKETS

OUR VALUED CUSTOMERS

About Us

ELEVATED STEEL

We are a TURNKEY solution! For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on the fabrication that is both high-quality and on time.

We strive to stand out from the rest of the fabrication and installation companies. We want to collaborate with our clients in every project we take on and to work with partners who are reliable and trustworthy.

OUR CUSTOMERS

WHY WORK WITH US?

Combining decades of cutting, forming and welding experience, Waterjet West has the experience, equipment and skilled staff to exceed expectations on every order!

ADVANCED

CAPABILITIES

Our modern equipment and processes enable us to deliver our customers' orders with shorter lead times and higher quality. Our Staff are dedicated to making our customers successful, one order at a time!

SUPERIOR

QUALITY

Quality is built in, such that getting it right the first time is the expectation. From our initial meeting to quoting to order delivery, our advanced product quality planning process is engineered to provide our customers with a reliable supply chain.

RELIABLE

DELIVERY

Driven by a deep sense of personal pride, each member of our staff is committed to ensuring absolute customer satisfaction. We refuse to accept mediocrity and we do everything in our power to deliver what we promised to our customers.

INDUSTRIES SERVED

MILITARY

CONSTRUCTION

MEDICAL

MANUFACTURING

AUTOMOTIVE

INDUSTRIAL

HOW WE ENSURE QUALITY

PROCESSES & CERTIFICATIONS

ITAR certified

AS9100d / ISO9001:2015 procedures implemented with certification expected Q2 2025

Quality Systems, Incoming Inspection, FAI, Final Inspection, Document Control, Calibration program

NIST 800 Cybersecurity expected Q4 2025

Lean Six Sigma Methodologies

CALIBRATION & MAINTENANCE

We calibrate the waterjet at the start of every job! Typically within +/-0.002".

Garnet Abrasive media is analyzed to determine the particle size distribution for the highest quality cuts.

Tilt-a-Jet taper compensation on multiple waterjets to eliminate taper for precise 90° edges on material as thick as 6"

Nozzle and other critical parts are monitored and replaced prior to failure to allow high precision cuts

Let’s talk about your project

CHECK OUT OUR RECENT PROJECTS!

FREQUENTLY ASKED QUESTIONS

What size sheets can you cut?

Our cutting and forming machines can handle sheets up to 60" x 120"

What Is Your Typical Lead Time?

Our goal is to get estimates send out within 24-48 hours, but sometimes difficult to source materials take more time. We will quote the current lead time with the estimate. This is generally 3-15 days depending on the size of your job and our current work load. We offer Expedite services for an additional fee that can be as fast as same or next day.

What is your accuracy?

It depends on the material and the equipment we use, but we can hold tolerances as low as 0.005" for most applications.

How thick can you cut?

Our equipment can cut material from 0.001" to 6" thick of nearly any material!

What Are The Benefits of Waterjet Cutting?

Waterjet CNC cutting is the premier method for cutting most materials. There is no heat affected zone that can affect temper and cause work hardening so the machinists prefer waterjet cuts over laser, plasma, and torch cutting. The waterjet is ideal for composites that are difficult to cut on a CNC router. The narrow kerf allows higher yields.

What Types of Files Do You Work With?

Ideally, we'd prefer a dxf file in imperial units with only the cut profile (no dimensional data). We can also use Illustrator (.ai), .svg, .stl, .sldprt, and most other CAD files (except for Corel Draw).

If you don't have a file, our engineers can reverse engineer any flat part. If your part is small enough to fit on a standard printer / scanner, you can send us a pdf of the scan. If the part is larger you can either trace it on white paper, or bring it in for us. We have a 36" wide roll feed scanner to convert traces of large parts with high accuracy. If you can leave the part with us until the job is complete that is preferred. We will laser cut a paper template to verify the conversion is accurate before we cut your parts out of the material of your choice.

ABOUT WATERJET WEST

YOUR LOCAL PARTNER FOR LASER CUTTING AND FORMING

Since 2005, Waterjet West has been providing customers in California and surrounding states with reliable, cost efficient fabrication solutions. With an experienced leadership team with backgrounds in engineering, quality management, FDA regulations, automation, and Six Sigma Methodologies, our expertise enables us to design and implement highly efficient fabrication solutions for our customers.

With our modern fabrication shop located in Southern California, we are a full-service waterjet, laser cutting, and metal forming partner, dedicated to providing quality, cost-effective fabrication solutions.

Our specialized capabilities and customer-centric culture enable us to adapt to our clients' evolving needs, ensuring the success of every project. Our team of skilled professionals are committed to delivering on our promises.

When you choose Waterjet West, you're not just choosing a supplier; you're choosing a partner dedicated to your success.

When you choose Waterjet West, you're not just choosing a supplier; you're choosing a partner dedicated to your success.

Let’s talk about your project

Connect With Our Team!

Fill out the form and we'll be in touch within 2 hours!

Want To Reach Out Directly?

There's almost no job we can't handle,

so let us know how we can help!

Manufacturing Plant Location:

330 S Pacific St, Ste C

San Marcos, CA 92078

Office Hours:

Monday - Friday

8:00 am to 5:00 pm

Phone:

760-452-3531

Let’s talk about your project

WATERJET WEST

We're your local partner for waterjet, laser cutting, and metal forming!

Reach out for an accurate quote and reliable delivery!

EQUIPMENT WE USE

Voortman V807

Plasma Cutter

EMI EL2

20’ brake

20’ shear

WE FOCUS ON QUALITY

AISC Compliant

Every part is quality checked

Certified Welders – 1,2,3,4G certifications (MIG and stick welding), GMAW and SMAW

AWS D1.1 compliant

LET'S TALK ABOUT YOUR PROJECT

For decades, we’ve built our business on consistently going above and above for our customers. We pride ourselves on fabrication that is both high quality and on time. We collaborate with our clients on every project we take on and to work with partners who are reliable and trustworthy.

Reach out to us by calling us or filling out this form and we will be in touch to talk about your project as soon as we can.

CONTACT INFORMATION